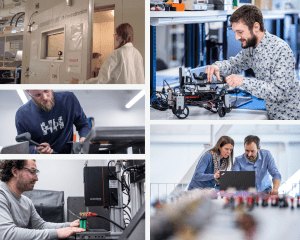

Our centres of expertise

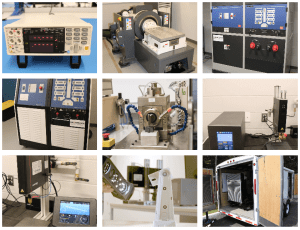

- Electrical: Vehicular platform electrification projects, battery projects for the aeronautics or land transportation sector, and smart charging projects for vehicle fleets.

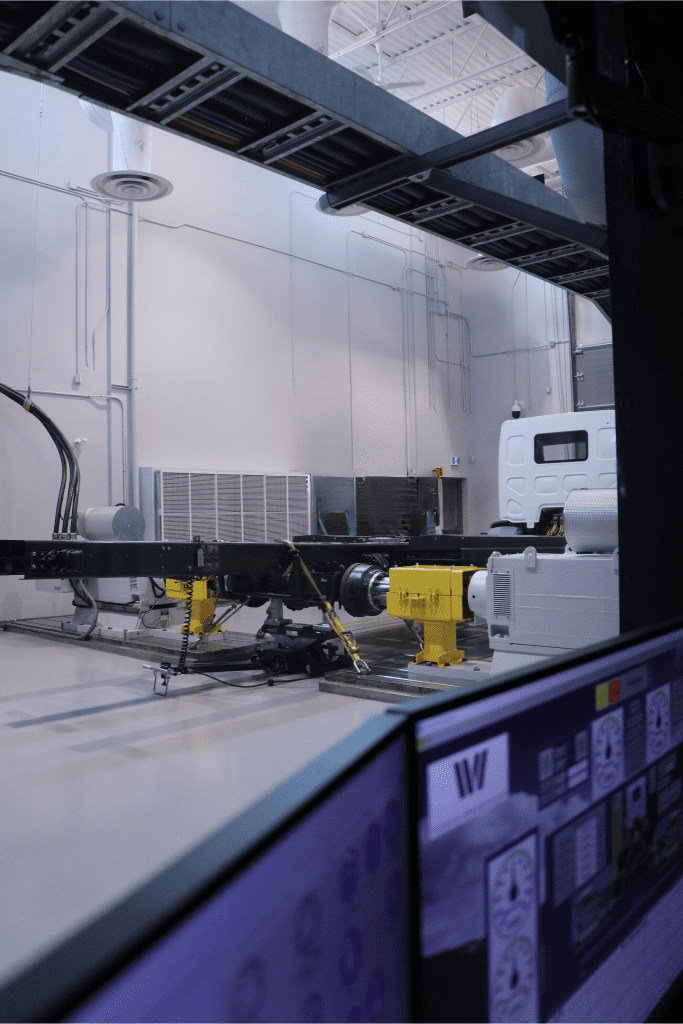

- Mechanical: Design and integration of electric vehicles, particularly battery thermal management and development and implementation of traction systems.

- Software: Vehicle and technology automation projects, such as robotization and artificial intelligence applied to vehicles.

- Technological applications: Supporting companies in the deployment of their new technologies, under actual conditions of use.